The first-ever

Mobile Winding Solution.

INSIGHT

Out of the total installed generators worldwide, 40% are 40 years old or even older.

Out of the total installed generators worldwide, 40% are 40 years old or even older.

INSIGHT

Out of the total installed generators worldwide, 40% are 40 years old or even older.

PROBLEM

With today’s operating regimes, the insulation system has been pushed to its limits, resulting in insulation breakdown and, consequently, generator shutdown.

Incidents like winding breakdowns are becoming increasingly likely, causing unplanned outages and affecting availability for further operational use.

With today’s operating regimes, the insulation system has been pushed to its limits, resulting in insulation breakdown and, consequently, generator shutdown.

Incidents like winding breakdowns are becoming increasingly likely, causing unplanned outages and affecting availability for further operational use.

PROBLEM

With today’s operating regimes, the insulation system has been pushed to its limits, resulting in insulation breakdown and, consequently, generator shutdown.

Incidents like winding breakdowns are becoming increasingly likely, causing unplanned outages and affecting availability for further operational use.

CURRENT PROCESS

Significant time for organizing the production of replacement windings and for the actual rehabilitation process.

These processes often extend beyond 4 months, unnecessarily prolonging generator downtime which is resulting in lost revenue for the owner.

Significant time for organizing the production of replacement windings and for the actual rehabilitation process.

These processes often extend beyond 4 months, unnecessarily prolonging generator downtime which is resulting in lost revenue for the owner.

Significant time for organizing the production of replacement windings and for the actual rehabilitation process.

These processes often extend beyond 4 months, unnecessarily prolonging generator downtime which is resulting in lost revenue for the owner.

Only several VPI producers in the world

Expensive to install and run

Requiring specific machines, processes, and know-how

120+ days of shutdown

Only several VPI producers in the world

Expensive to install and run

Requiring specific machines, processes, and know-how

120+ days of shutdown

Only several VPI producers in the world

Expensive to install and run

Requiring specific machines, processes, and know-how

120+ days of shutdown

SOLUTION

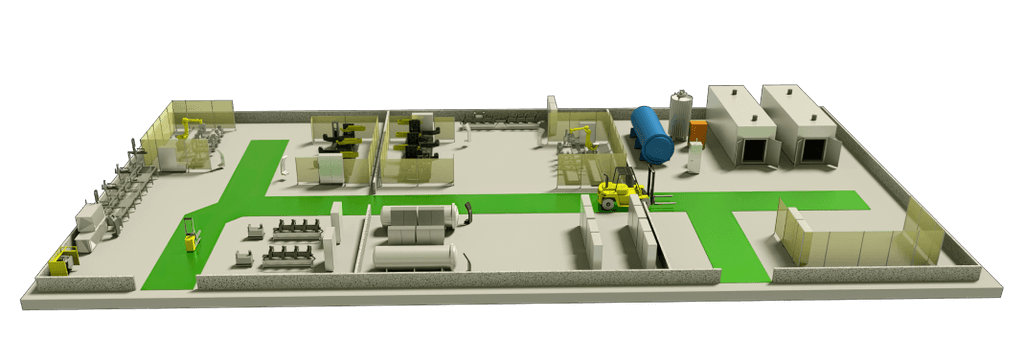

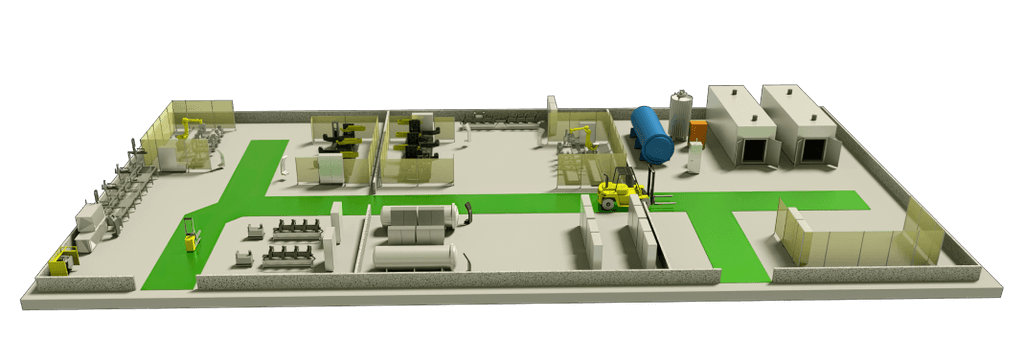

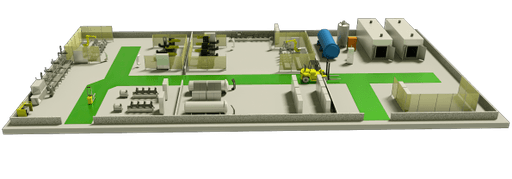

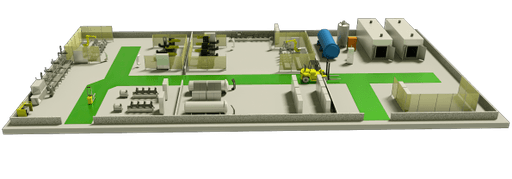

OLM MG mobile winding solution offers significant time saving in processes of reinsulation of stator bars.

OLM MG mobile winding solution offers significant time saving in processes of reinsulation of stator bars.

OLM MG mobile winding solution offers significant time saving in processes of reinsulation of stator bars.

By presence of OLM at place of need, work will be done in minimal time frame enabling that generator is ready for active operational work and available to the network operator.

Full equipement for bar reinsulation

First ever mobile VPI technology

Ready to start at any place at the time of bar extraction

No need for special transport

Standard power and air connections

ECO – friendly

aprox. 50 days of shutdown

Full equipement for bar reinsulation

First ever mobile VPI technology

Ready to start at any place at the time of bar extraction

No need for special transport

Standard power and air connections

ECO – friendly

aprox. 50 days of shutdown

By presence of OLM at place of need, work will be done in minimal time frame enabling that generator is ready for active operational work and available to the network operator.

Full equipement for bar reinsulation

First ever mobile VPI technology

Ready to start at any place at the time of bar extraction

No need for special transport

Standard power and air connections

ECO – friendly

aprox. 50 days of shutdown

The downtime of the generator due to breakdown is reduced to minimum.

Machine disassemble

Machine disassemble

21

21

20

0

15

0

30

8

3

3

15

0

21

21

Contract reinsulation

Contract reinsulation

Winding transport to factory

Winding transport to factory

Reinsulation

Reinsulation

Winding test

Winding test

Winding transport to site

Winding transport to site

Machine assembly

Machine assembly

STANDARD PROCESS

OLM MG

125

53

DAYS OF SHUTDOWN

Eco- friendly

The OLM MG system is safe and environmentally friendly. There are no exhaust gases, no liquid discharges, and no need for their disposal.

The OLM MG system is safe and environmentally friendly. There are no exhaust gases, no liquid discharges, and no need for their disposal.

Additional filters and safety elements can be installed according to specific customer requirements to further enhance safety during the process execution.

Additional filters and safety elements can be installed according to specific customer requirements to further enhance safety during the process execution.

CONTACT US

CONTACT US

CONTACT US

Zvonarnička ulica 3, 10 000 Zagreb, Croatia